Reach your potential and beyond in Smart Manufacturing

Monoid Solutions is an automation solutions provider for the electronics and semiconductor manufacturing industry.

We help our customers achieve their Industry 4.0 and IoT goals of implementing secure and reliable data collection from their operating environments and equipment to boost efficiency, productivity, profitability and reliability. Our well designed, reliable and economic solutions with a focus on your specific automation needs help cut costs and fuel growth.

We have over 30 years of experience in developing automation solutions in embedded software, PLC programming, Windows applications and Web applications.

We are well equipped to link new proprietary systems from various manufacturers to legacy systems and also to MES, ERP and other supply chain applications.

We take pride in our broad based and deep expertise!

- Windows applications

- DOS Applications

- PLC Programming

- Serial, SECS/GEM, TCP/IP, HSMS Communications Protocols

- Microcontroller Programming

- Web Applications

- Database Design and Applications

Our Products

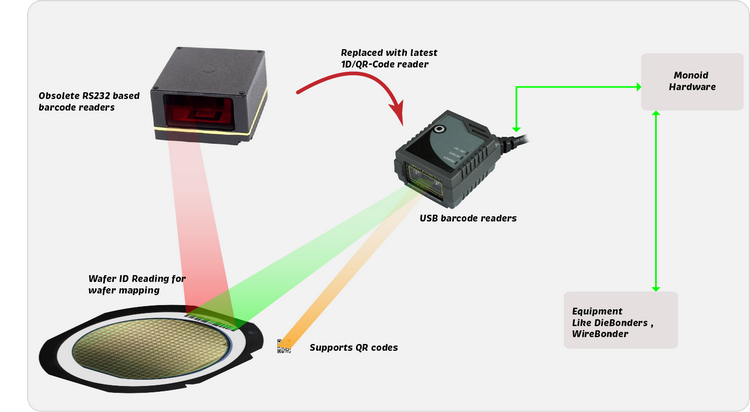

Legacy Machine Wafer ID Reader Kit

The Croz-Code kit (H/w & S/w) enables the replacement of obsolete serial barcode readers on legacy machines with a newer barcode reader model. This enables you to extend the lifespan of legacy machines.

Main features

- New barcode reader has the ability to read printed 1D and QR/2D codes

- Compared to legacy readers, the latest barcode readers are designed to read faster.

- Able to read barcode labels that are low-contrast, soiled, or damaged.

- Ultra-compact and easy mounting design for flexible integration

- Outstanding reading capability on 3 mil barcode with more than 3 depth of field

- The machine requirements can be met easily through calibration.

- Croz-Code can be customized to replace ANY previous serial barcode reader.

Main Advantages:

No modifications to the machine software are necessary.

Monoid server (a Windows-based PC) is capable of connecting 32 barcode readers.

There is no impact on the equipment performance or calibration procedures.

In most cases existing mounting brackets can be reused for new barcode readers

HSMS Capabiplity for legacy machines

ACQYR is our star application for the digitisation of manufacturing with interconnectivity and access to real-time data.

Main features included are as below:

Machine control

Real-time data collection

Remote Monitoring

Productivity Monitoring

Operator Tracking

MES Integration

Messaging through TCP/IP message exchanges (sockets), FTP, Serial Port and PLC communication

HSMS capabilities for all machine types

- Process & Machine status capture

- Alarm capture

- Machine specific events

- Recipe upload/download

- Terminal messages

- Wafer mapping (Die-Bonders only)

- Reject/Strip mapping (Die-Bonder, Wire bonder & X-ray machines)

- E-84 integration with other modules

Mold M/c Specific features

- Active number of press for OEE/PTE

- Cleaning status of each press

- Events for press up and down to control the press life time

- Lead frame IN/OUT events

X-Ray M/c Specific features

- Idle time control

- Parameter control

- Optional Recipe control if m/c is not capable

- Lot control

- Product control to avoid using the m/c for wrong devices

Main Advantages

- Connect non SECS/GEM or SECS-1 machine to HSMS host

- HSMS Messages can be customized to suite the customer host

- M/c performance is not affected

- No changes in the existing M/c software or hardware

- Plug and play modules

- Optional MES integration

Machine models upgraded successfully

| Die Bonder | Wire Bonder | Mold | Test handler | Inspection M/c | Oven | Plasma |

|---|---|---|---|---|---|---|

| ESEC 2007/2008 ASM 838 ASM 8912 ASM Die+Clip attach Alphasem Die+Clip attach |

ASM Eagle Orthodyne |

Dai-Ichi GPZ TOWA Y1R/Y1E TOWA YPS TOWA YPM ASAHI |

ISMECA-NX16 TOWA Y ASM ST209 |

X-Ray M/c Offset M/c |

Blue-M MSL |

Quadrio 4/5 |

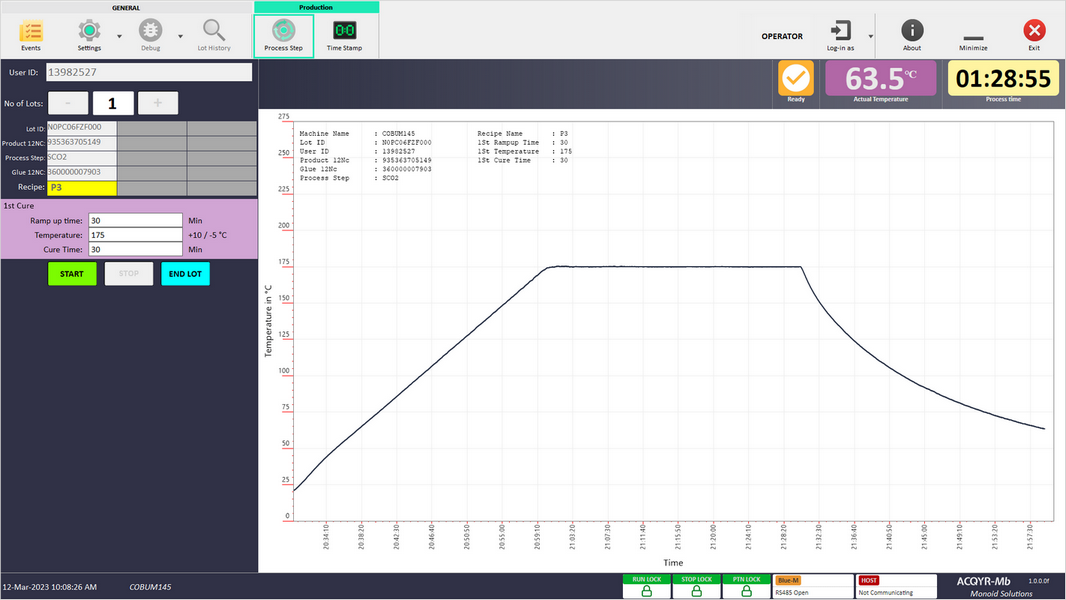

ACQYR-Mb™ kit enables Blue-M /MSL Oven machines to connect to Host via HSMS and enables paperless automation by eliminating Circular chart recorder

ACQYR-Mb ™ runs on a Windows Micro computer and supports communication with a single oven machine.

Main features

- Host connection via SECS/GEM

- Curing recipe/programs management

- Curing program lock on Oven controller

- Oven temperature & O2PPM graph display (eliminates the Circular chart recorder)

- Lot control, allows more than 1 lot to run

- Oven Start/Stop control

- Time stamp label on the graph for quality assurance inspection

- Real time logging of temperature and other run data for each Lot

- Real time logging of O2PPM

- User Access control and management

- Event logging

- Lot history

Main Advantages:

- Improved quality

- Reduced scrap lot

- Paperless (Reduce cost)

- Minimised Lot hold time due to reduced manual interventions

- Reduction on in manual tasks by QA and PM Staff to record temperature observation data

- Easy tracing of lot information

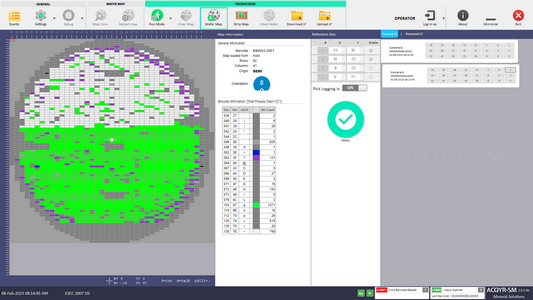

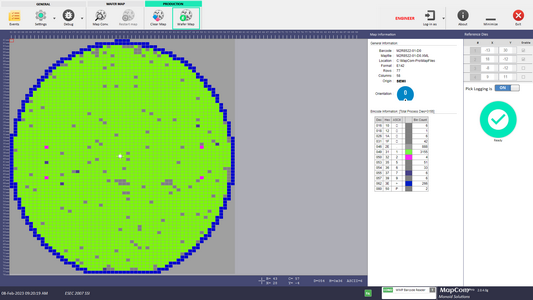

MapCom-Pro™ is our software application that enables wafer mapping for semiconductor equipment for the indentification and traceablity of problems in the wafer fabrication process.

It is an invaluable tool to lower costs, improve quality and increase yields.

MapCom-Pro™ runs on a Windows computer and supports communication with a single machine that is SECS/GEM compatible.

The standard package includes one map data format which will be converted to SECS/GEM format before loading to the equipment.

MapCom-Pro™ provides optional conversion of custom map data format from different probers.

Main features

- Loading of map data from local hard disk/network drive

- Conversion of custom map data format to machine format before process

- Save processed map data for further process/data analysis

- Configurable map storage (directory and extension)

- Supports different origin formats

- Individual bin-code color setting

- Maximum of 4 reference datum transfer to the machine

- Map zoom and pan functionalities for small die wafers.

Optional features

- Loading of map data from local hard disk/network drive

- Conversion of custom map data format to machine format before process

- Save processed map data for further process/data analysis

- Configurable map storage (directory and extension)

- Supports different origin formats

- Individual bin-code color setting

- Maximum of 4 reference datum transfer to the machine

- Map zoom and pan functionalities for small die wafers.

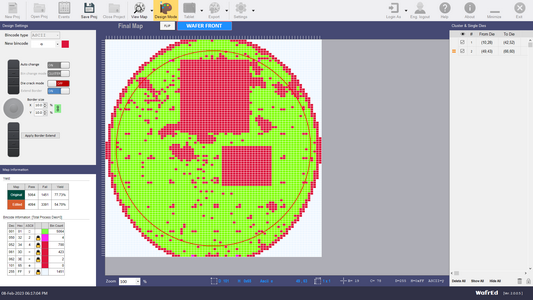

WafrEd™ is a feature rich application to edit semiconductor wafer map data and modify the individual bin or bin clusters easily.

WafrEd makes the engineer's job easier by allowing him to visually edit the map data and mark with different bin codes for selective picking of dies. Selective picking is required in cases of broken wafers, scratched dies, cracked dies etc.

WafrEd™ allows the user to save the bin code modifications as a WafrEd™ project file, that can be re-edited if required.

A WACOM graphic tablet can be connected to easily navigate the on-screen display of the wafer map and select the individual dies for editing.

Main features

- Supports standard ASCII map data file with header and footer.

- Optional support for custom map formats.

- Individual or cluster bin edits

- Cluster edits can be done in rectangular blocks

- Can set desired colour for each bin-code

- Display of map bin codes in Hex, Decimal and ASCII formats

- Retrievable edits

- View of edited and unedited bins for easy comparison

- Comparison chart for modified and original bin codes

- Lock/Unlock editing of bin codes (e.g. Null bin code, Process bin codes)

- Easily convert several bin codes to a single bin code

- Export modified map to TXT file for processing on machine

Optional features

- Create customized editing templates.

- User definable edge-die editing

- User definable wafer split

- Export modified map to custom format.

- Batch editing of multiple wafers with a chosen template.

- Interfacing with our product MapCom to download map directly to the machine through SECS/GEM.

WafrEd-Pro features

- Easy handling of cracked dies on wafer

- Die selection through wafer front/wafer back mode

- Die selection via electronic pen

- Easy Wafer border die extension

We have upgraded over 700 machines

Our valued customers are

NXP Semiconductors

NEXPERIA

STMicroelectronics

Integrated Micro-Electronics Inc.

Locate Us

Monoid Solutions Pte. Ltd.

Tampines Street 84 , Singapore 520875

© 2025 Monoid Solutions Pte. Ltd. | All Rights Reserved